Combining Roof Repairs with Coatings: A Two-Step Fix for Leaking Metal Roofs

Manns Choice, United States - October 15, 2025 / Choice Roofing Services /

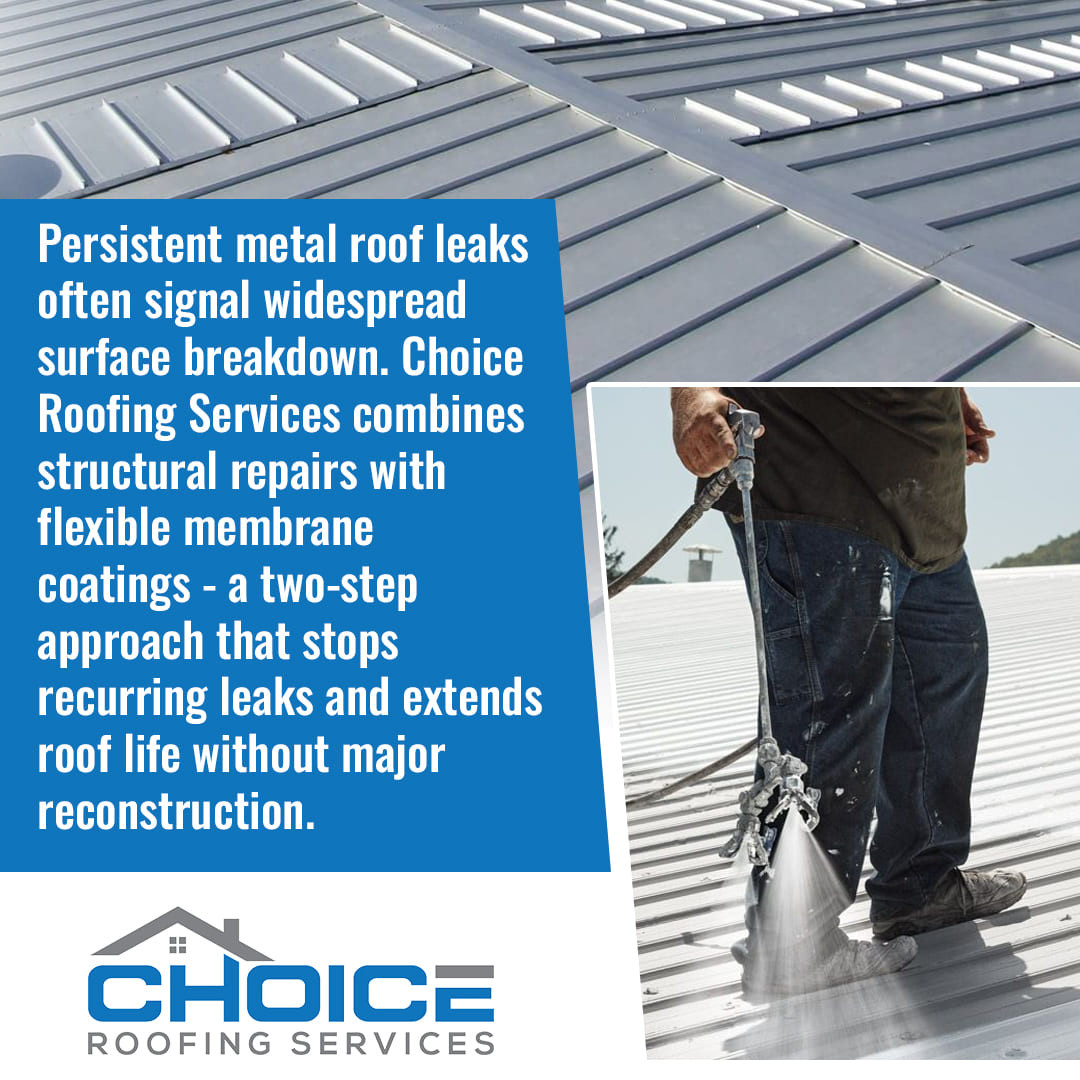

Bedford, PA - Many metal roofs in Central Pennsylvania begin to leak long before they reach the end of their structural life. Repeated roof repairs can delay damage, but unless the root cause of the leaks is addressed, the same problems often reappear. Choice Roofing Services, LLC, a trusted roof repair company serving Bedford, Altoona, Johnstown, Somerset, and McConnellsburg, offers a long-term solution by combining structural repair work with flexible membrane coatings to stop active leaks and prevent future deterioration.

Why Traditional Repairs May Not Be Enough

Over time, metal roofs expand and contract with temperature shifts. This constant movement stresses fasteners, panels, and seams, which are common weak points where water finds its way inside. Many homeowners patch individual leak locations, only to face new problems a few months later. Isolated roof repairs may seem cost-effective at first, but they often fail to resolve systemic wear affecting large areas of the roof.

Fastener holes widen, seam connections loosen, and flashing around chimneys or vents degrades over time. Once one section begins to fail, others typically follow. In these cases, a more strategic two-step approach is recommended.

A Proven Two-Part Process for Lasting Protection

The two-step method involves targeted structural roof repairs followed by the application of a liquid membrane coating. This combination restores both function and protection to aging metal roofing systems.

Step 1: Structural Roof Repairs

Professional roof repair contractors inspect the entire roofing system to identify weakened fasteners, damaged panels, and failed flashing. These components are repaired or replaced to restore the integrity of the roof structure. Without this essential first step, surface coatings may not adhere properly or deliver the expected performance.

Step 2: Application of Membrane Coating

Once repairs are completed, a seamless liquid membrane is applied to the entire roof surface. This flexible coating bonds tightly to the metal, bridges small gaps, and prevents water infiltration at vulnerable areas. Because the membrane can flex with the roof's natural movement, it remains intact longer than rigid sealants or patch materials.

Roof Conditions That Qualify

This two-step solution is ideal for roofs that are structurally sound but showing signs of surface wear. Widespread rusting, seam separation, and failing coatings across the roof surface all indicate that the protective layer has broken down, even if the base structure remains viable.

A professional roof repair company will evaluate whether a roof is a good candidate for restoration or if full replacement is necessary. The extent of corrosion, water damage, and fastener wear all play a role in that assessment. For many aging roofs, restoration offers a cost-effective alternative to full replacement.

Benefits of Membrane Coating

One of the key benefits of this approach is its financial efficiency. The total roof repair cost of combining structural work with a coating application is typically far less than full roof replacement. Additionally, reflective membrane coatings reduce heat absorption, which can lower energy bills during summer.

Future recoating options also make long-term maintenance more predictable and affordable. Property owners can preserve their investment by reapplying the membrane as needed rather than rebuilding the entire roof system.

Environmental Stress in Central Pennsylvania

Weather extremes in Central Pennsylvania create ideal conditions for metal roof deterioration. Freeze-thaw cycles strain joints and seams throughout winter. In summer, intense UV exposure weakens protective layers. Nearby trees add organic debris and trapped moisture, while industrial areas expose roofs to chemical contaminants.

These conditions increase the demand for protective coatings that adapt to shifting weather patterns. Unlike rigid repairs that often fail under stress, flexible membranes protect repaired surfaces from both mechanical and environmental wear.

Choice Roofing Services: Your Local Partner for Roof Repairs and Restoration in Central Pennsylvania

Choice Roofing Services delivers this two-step solution to property owners throughout Central Pennsylvania looking for durable results. Whether you're dealing with multiple leak points or surface wear from years of weather exposure, our team provides clear assessments and reliable solutions.

If you're searching for roof repair near you, work with a team that understands the unique challenges of Central Pennsylvania's climate. As a proven roof repair company, Choice Roofing Services uses time-tested materials and regional expertise to solve persistent roofing issues with minimal disruption and long-term benefits. To schedule a professional inspection or learn more about your roof repair options, contact Choice Roofing Services at (814) 410-1409 or daniel.choiceroofing@gmail.com today.

Contact Information:

Choice Roofing Services

4156 Glade Pike

Manns Choice, PA 15550

United States

Daniel Fisher

https://callchoiceroofing.com/

Original Source: https://callchoiceroofing.com/combining-roof-repairs-with-coatings-a-two-step-fix-for-leaking-metal-roofs/